We Have The Best Solutions for Your Business

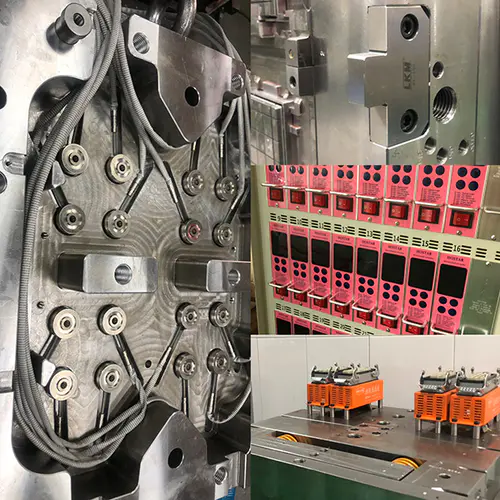

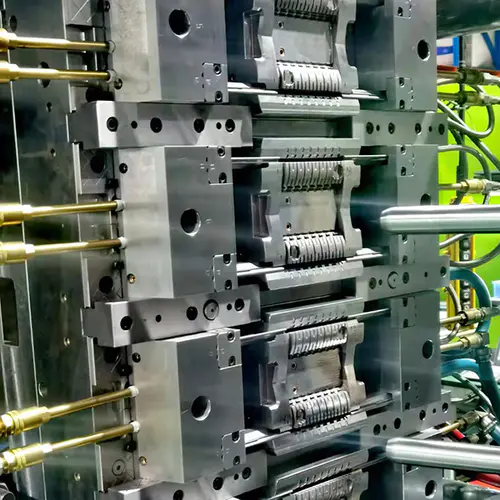

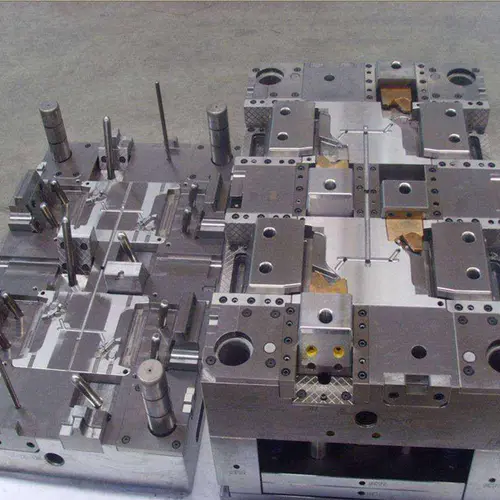

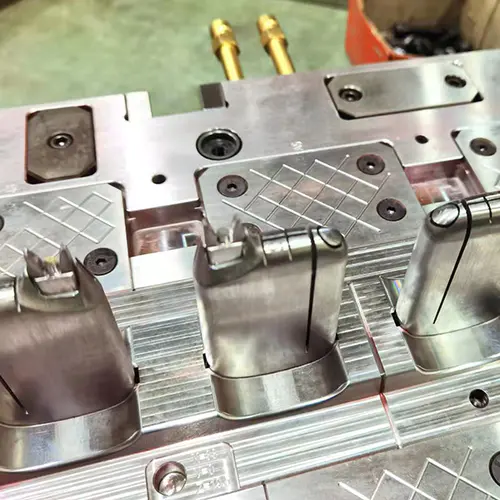

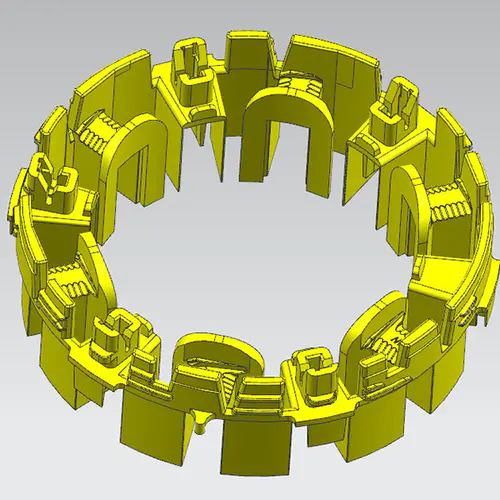

Jiajie Company was established in October 2003, located in Dongguan City, Guangdong Province, China, covering an area of more than 3,000 square meters, and established a branch in Phnom Penh, Cambodia. The company is mainly engaged in the design and manufacture of plastic molds and injection molding production. Years of experience in ordinary plastics, special engineering plastic molds and injection molding, such as PPS, PEEK, PES, LCP, PC, PA and other engineering plastic products, for large-scale injection products, we give priority to hot runner molds, which not only ensures product quality , and reduce the production cost. The company's products are mainly used in automobiles, instrumentation, headphones, construction machinery, intelligent terminals, etc.

The company has more than 20 technical personnel of various types, including 5 senior engineers. It has more than 30 sets of various mold processing and testing equipment such as CNC machining centers, mirror spark machines, slow wire walking machines, three-dimensional measuring tools, etc., and uses PRO-E, UG, CAD, CAE and other software for design and development work. The production department has two More than ten injection molding machines of different tonnages are dedicated to mass production, and are equipped with a complete set of injection molding production auxiliary systems, such as small robots, manipulators, video surveillance, automatic feeding systems, etc., to achieve fully automated production.

The Role of Pes Plastic Mold

PES plastic mold is widely used in the natural gas industry due to its excellent chemical resistance, high-temperature stability, and superior mechanical properties. PES

One of the main advantages of PES plastic mold in the natural gas industry is its ability to withstand high temperatures. The material can maintain its structural integrity and mechanical properties even when exposed to temperatures of up to 200°C, making it ideal for use in high-temperature applications such as pipes, valves, and fittings.

PES plastic mold is also highly durable and resistant to wear and tear, making it suitable for use in demanding applications where components are subject to heavy use and abrasion. Additionally, the material's high strength and stiffness make it ideal for use in structural components of natural gas processing equipment.

Moreover, PES plastic mold is also highly resistant to hydrocarbons and other gases commonly found in natural gas environments. This makes it an ideal material for use in gas pipelines, where resistance to corrosion and chemical attack is essential.

User Reviews

What users say about JIAJIE

Frequently Asked Question

Do you have any question?

PES plastic mold is a high-performance thermoplastic material known for its excellent mechanical properties, high-temperature resistance, and dimensional stability.

PES plastic mold exhibits excellent mechanical properties, high-temperature resistance, dimensional stability, and resistance to chemicals and hydrolysis.

PES plastic mold is used in various industrial applications such as aerospace, automotive, medical, and electronics.

PES plastic mold can withstand temperatures of up to 200°C, making it an ideal material for use in high-temperature applications such as aerospace and automotive industries.

Our updates and blog posts

How are plastic molds classified?

Classified by molding (1) Injection molding is to first add plastic to the heating barrel of the injection machine. The plastic is heated and melted. Under the push of the injection machine screw or plunger, the nozzle and the mold casting system enter the mold cavity due to physical and chemical effects. The hardening is shaped into an injection molded product.

Multitasking Materials In Future Construction

We are a manufacturer of special engineering plastic mold manufacturer. If you have any needs for plastic molds, you are welcome to consult us!

Let's get to know the basics of plastic mold together

The shape of the mold determines the appearance of these products, and the processing quality and precision of the mold also determine the quality of these products.